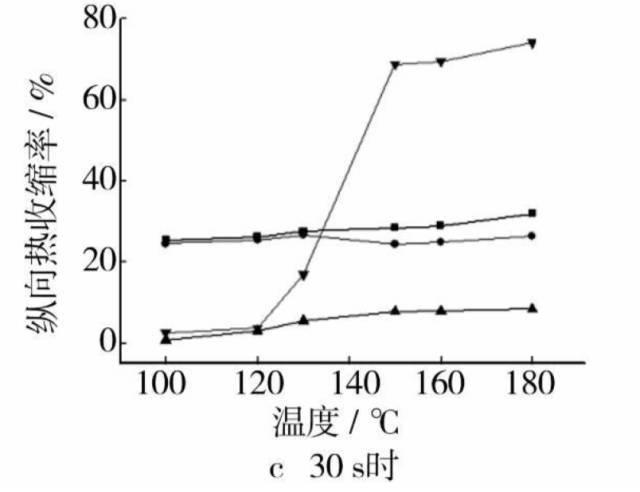

Production technology and principle of shrink film

Plastics include amorphous plastics and crystalline plastics. In the process of producing the film, the plastic is heated and melted, the force between its macromolecules is weakened, and the macromolecules are arranged in disorder. Even after the film is cooled, the macromolecules are still in an irregular state as long as the temperature is lower than the softening point. If the film is stretched when it is reheated to the high elastic state temperature of the polymer, the macromolecular chains will be regularly aligned along the direction of external force (stretching direction). At this time, the film is cooled and the orientation of the molecular segments is frozen. When the film is reheated, due to the activity of the molecular chain segment, the polymer has a tendency to restore its size before stretching (memory function). The stretched oriented film produces stress relaxation, the oriented film is de oriented, and the film shrinks and returns to the initial size along the original stretching direction. This is the thermal shrinkage of the film.

Analysis of longitudinal shrinkage of heat shrinkable film

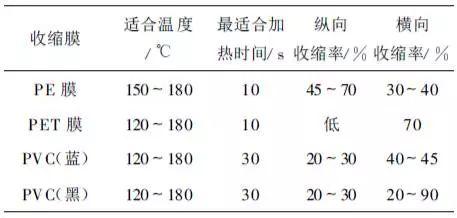

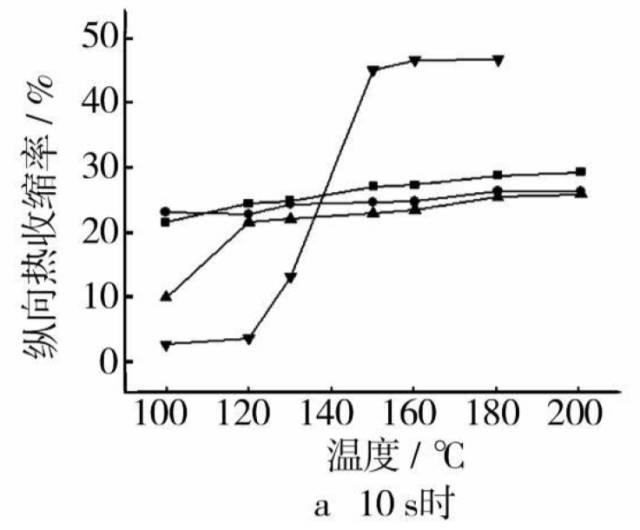

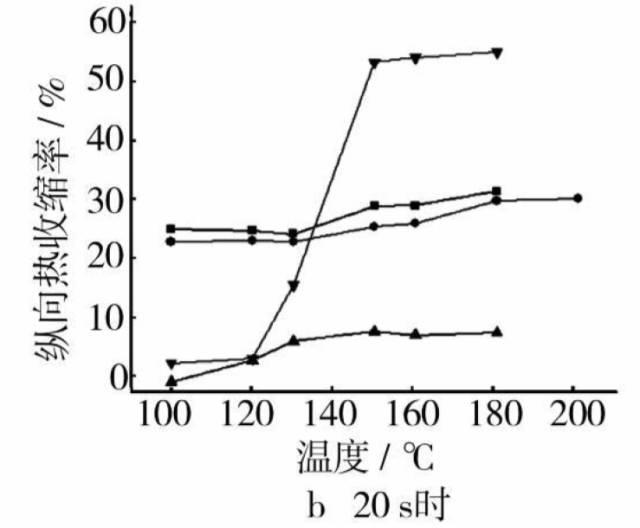

The longitudinal shrinkage length of the film is measured according to the changes of temperature and time, and the longitudinal shrinkage rate of the film is calculated, as shown in Figure 1.

It can be seen from Fig. 1a-c that the longitudinal thermal shrinkage of several heat shrinkable films in this test increases with the increase of heating temperature or heating time during packaging operation. Among them, the longitudinal thermal shrinkage of PE film increases the most, and the shrinkage can range from 45% to 70%. This can be explained from the following two aspects: first, the crystallinity of PE film is higher than that of the other three films. Generally speaking, The higher the crystallinity of the film, the closer the molecular arrangement and the higher the density, so the greater the shrinkage; On the other hand, the reason may be that the longitudinal tensile degree of PE film is also relatively high, so the thermal shrinkage is also relatively large. It can also be seen from Fig. 1a-c that PE film has good thermal stability in the range of 150 ~ 180 ℃. When PET film is heated at 100 ~ 120 ℃ for 10 s, the thermal shrinkage is also large, which may also be caused by its high crystallinity; However, with the further increase of temperature and heating time, the thermal shrinkage has little change, which may be caused by the low longitudinal tensile degree of pet thermal shrinkage film. There is little difference in longitudinal thermal yield between PVC and PVC, but because the crystallinity of PVC is slightly higher than that of PVC, its longitudinal shrinkage is also slightly higher.

Fig. 1 longitudinal thermal shrinkage temperature curve of film

Analysis of transverse shrinkage of thin film materials

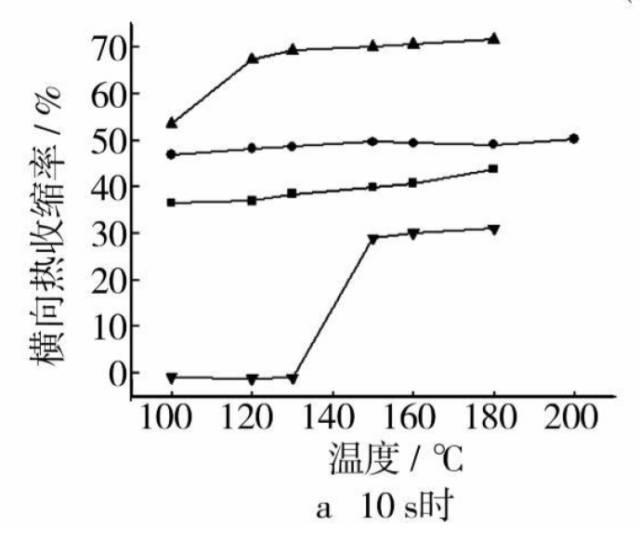

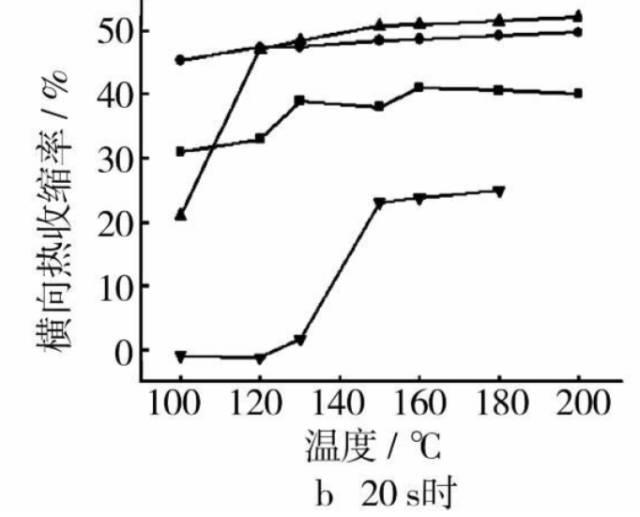

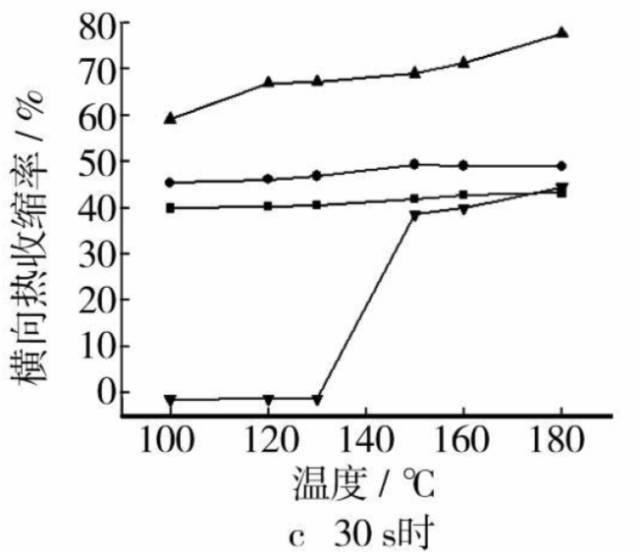

The transverse shrinkage length of the film is measured according to the changes of temperature and time, and the transverse shrinkage rate of the film is calculated, as shown in Figure 2.

Comparing figures 2a, B and C, it can be seen that the transverse thermal shrinkage still has a positive dependence on the heating temperature and heating time during packaging operation. The change trend with temperature and time is similar to the longitudinal shrinkage, but the shrinkage may be different due to the different degree of transverse stretching. For example, the transverse thermal shrinkage of PE film is about 30% ~ 40%, while that of pet can reach more than 70%, and that of PVC is 40% ~ 45%. It is considered that the main reason for the difference of the above transverse shrinkage is the different transverse tensile degree of these films. Comparing figures 1 and 2, the transverse thermal stability temperature range of these films is basically consistent with the longitudinal thermal stability range. For example, the transverse thermal stability of PE film is good in the range of 150 ~ 180 ℃; Pet has good thermal stability at 120 ~ 200 ℃.

Fig. 2 transverse thermal shrinkage temperature curve of film

Conclusion

Based on the longitudinal and transverse shrinkage of the above films, the characteristics of several heat shrinkable films can be compared, as shown in Table 1. PE film has shorter heating time, uniform vertical and horizontal shrinkage and lower cost, but the heating temperature range is narrow; PET film has high cost and high transverse shrinkage, which may be more suitable for the process design of transverse shrinkage; Compared with the first two materials, PVC film has moderate cost and uniform vertical and horizontal shrinkage, but the heating time is slightly longer. PVC is black with slight impurities, and PVC has good light transmittance.

In production, different packaging materials can be selected according to the cost and different design schemes. For example, for the heat shrinkable film for printing pictures and texts, it is required to have a balanced vertical and horizontal heat shrinkage rate; For soft packaging, excessive thermal shrinkage will deform the object; For cylindrical hard objects, high transverse thermal shrinkage is required to make the film close to the object. Because the actual thermal shrinkage of the heat shrinkable film is often determined by the size of the packaged object, it is not necessary to reach its maximum thermal shrinkage in the practical application of the heat shrinkable film, which can be adjusted according to the actual requirements.